Profound and Detailed

WirelessHART Pre-test Process

2023-09-01

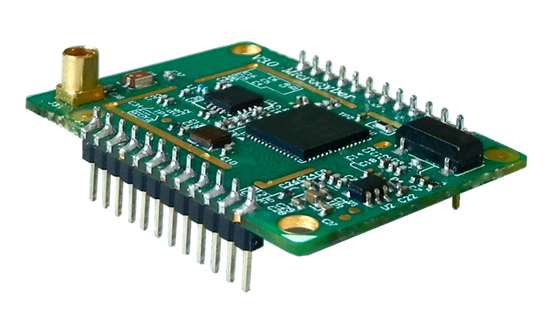

WirelessHART is a wireless technology dedicated to the field of process automation. It adds wireless functions to the HART protocol and is compatible with existing HART devices, commands and tools. Compared with wired HART device pre-test, the period of WirelessHART device pre-test is longer and more complicated, especially the test of the wireless part. In order to pass the WirelessHART product certification more conveniently and quickly, many customers choose Microcyber's M1100S wireless module, which greatly shortens the development and pre-test cycle. This article combines Microcyber's many years of HART/WirelessHART pre-test certification experience to introduce the basic process of WirelessHART device interoperability pre-test.

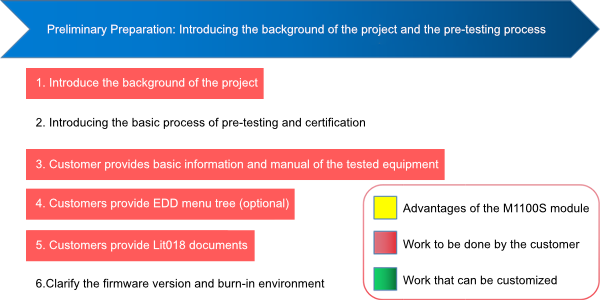

Initial Preparation Work:

To do a good job, an artisan needs the best tools. Good communication is the necessary basis for project development. Customers need to introduce the basic situation of the equipment to Microcyber, and Microcyber should also introduce the basic process of pre-testing and the approximate time node planning to customers. If it involves the development of EDD, the customer needs to provide the EDD menu tree and Lit018 document, where the Lit018 document is the document required for certification, and the content and format must be written in strict accordance with the requirements. Clarify the firmware version and programming environment. If it involves assistance in development, the customer also needs to provide the software development and compilation environment.

Since the tester is required to change the state of the device at any time during the pre-test, the customer needs to implement custom emulation special commands in the embedded code. Finally, the two sides confirmed the test schedule, and the preparatory work was basically completed.

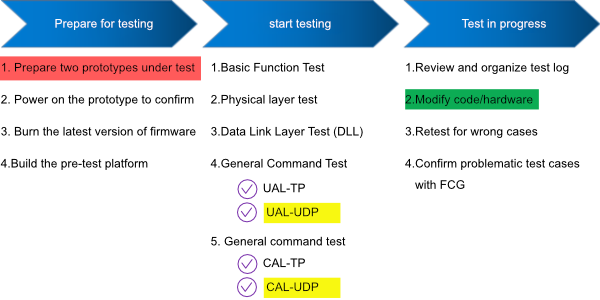

Start Testing:

After confirming that the prototype is complete, the unified firmware is programmed, and the power is correct, it is first necessary to perform a basic online test on the device, and use the serial port or WirelessHART-MPT debugging tool to test whether the device can read and write HART basic commands normally. If there is no problem, the hardware engineer will start the physical layer test and output the physical layer test report. Generally speaking, the DLL test needs to start after the physical layer test is completed. After the DLL test is completed, the UAL-TP, UAL-UDP, CAL-TP, and CAL-UDP tests will start. At the same time, the software engineer will review the messages and test logs generated by the test. If there is a failure item, it is necessary to communicate with the customer about the solution, modify the software, and retest again. Finally, it is necessary to ensure that all the above-mentioned test cases pass. , we can start the test of TML and SLT. TML and SLT tests are cumbersome, and it will be more complicated and difficult to determine the problem review log. However, if the device uses the M1100S wireless module, the TML and SLT tests only have time problems and no technical problems.

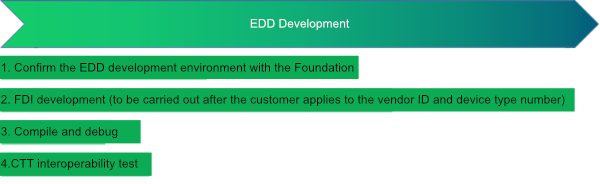

If the customer does not have the development ability, it is recommended to choose Microcyber to assist in the development of EDD. Microcyber has rich experience in EDD development. Moreover, since the foundation will only accept the certification of the new version of FDI in the future, which involves many problems and details, developers still need to repeatedly test and confirm FDI before submitting FDI certification.

End the Test:

After the test is completed, all the test logs need to be sorted out, and at the same time, the certification materials should be filled in and packaged, and finally the materials should be uniformly sent to the customer. During the certification process, Microcyber will provide technical support services throughout the process.

The above is the full introduction of the pre-test process. If you are interested, welcome to communicate with us.

<< Previous page

Next page >>