Profound and Detailed

Special Applications for Dual-channel Temperature Transmitters

2024-08-15

At various types of industrial production sites, temperature measurement points are most widely distributed. Important and key measurement points will use two temperature transmitters each connected to a single sensor or one temperature transmitter connected to two sensors, in order to achieve the purpose of enhancing reliability, safety, accuracy, etc.

1. Reliability and security - sensor redundancy backup

1. Reliability and security - sensor redundancy backup

The applicable working environment of the temperature transmitter is much better than that of the sensor. Except for special application requirements, a combination of one transmitter connected to two sensors is generally used. When the sensor works in important and critical environments such as high temperature, high pressure, corrosion, erosion and other harsh working conditions, in order to ensure stable output of measured values, when one sensor fails, the output signal of the temperature transmitter automatically switches to use another one. Sensor measurement results. When the faulty sensor is restored, you can choose to restore the original settings of the temperature transmitter.

2. Improve accuracy and special applications-arithmetic operations

A temperature transmitter connected to two sensors can calculate the average value of the two temperature values as the measurement result, which can improve the measurement accuracy. The two temperature values are added together in order to realize the special application of the combination of the two sensors. The two temperature values at the same measuring point are subtracted. When the difference reaches a certain set value, it is used as an alarm condition for sensor and circuit failure.

3. Signal conversion

The basic function of a temperature transmitter is to measure resistance and voltage signals, that is, the temperature transmitter can convert resistance signals and voltage signals within a certain range into standard signal output.

Example 1: Convert the linear resistance signal of the resistance magnetic float level sensor into a fieldbus level signal such as HART, PROFIBUS PA, FF H1, etc.

Example 2: Insert a high-precision, low-temperature drift resistor into the 4~20mA current signal loop, and the temperature transmitter measures the voltage at both ends of the resistor, which can convert the 4~20mA signal into fieldbus signals such as HART, PROFIBUS PA, FF H1, etc. PROFIBUS PA and FF H1 protocols can be converted into measured values such as length, pressure, temperature, etc. through the settings of the AI function block. See picture below:

4. Microcyber's dual-channel temperature transmitter

NCS-TT105H dual-channel HART protocol intelligent temperature transmitter

NCS-TT105P dual-channel PROFIBUS PA protocol intelligent temperature transmitter

NCS-TT105F dual-channel FF H1 protocol intelligent temperature transmitter

● Passed HART, PROFIBUS, FF certification

● Passed the explosion-proof and explosion-proof certification of the national explosion-proof station

● Supports dual-channel 10 types of thermal resistors and 9 types of thermocouples

● The thermoelectric anode supports 2, 3, and 4-wire wiring methods

● Thermocouple cold end compensation accuracy can reach ±0.5℃

● High precision 0.05%FS (normal temperature), low temperature drift (50ppm/°C)

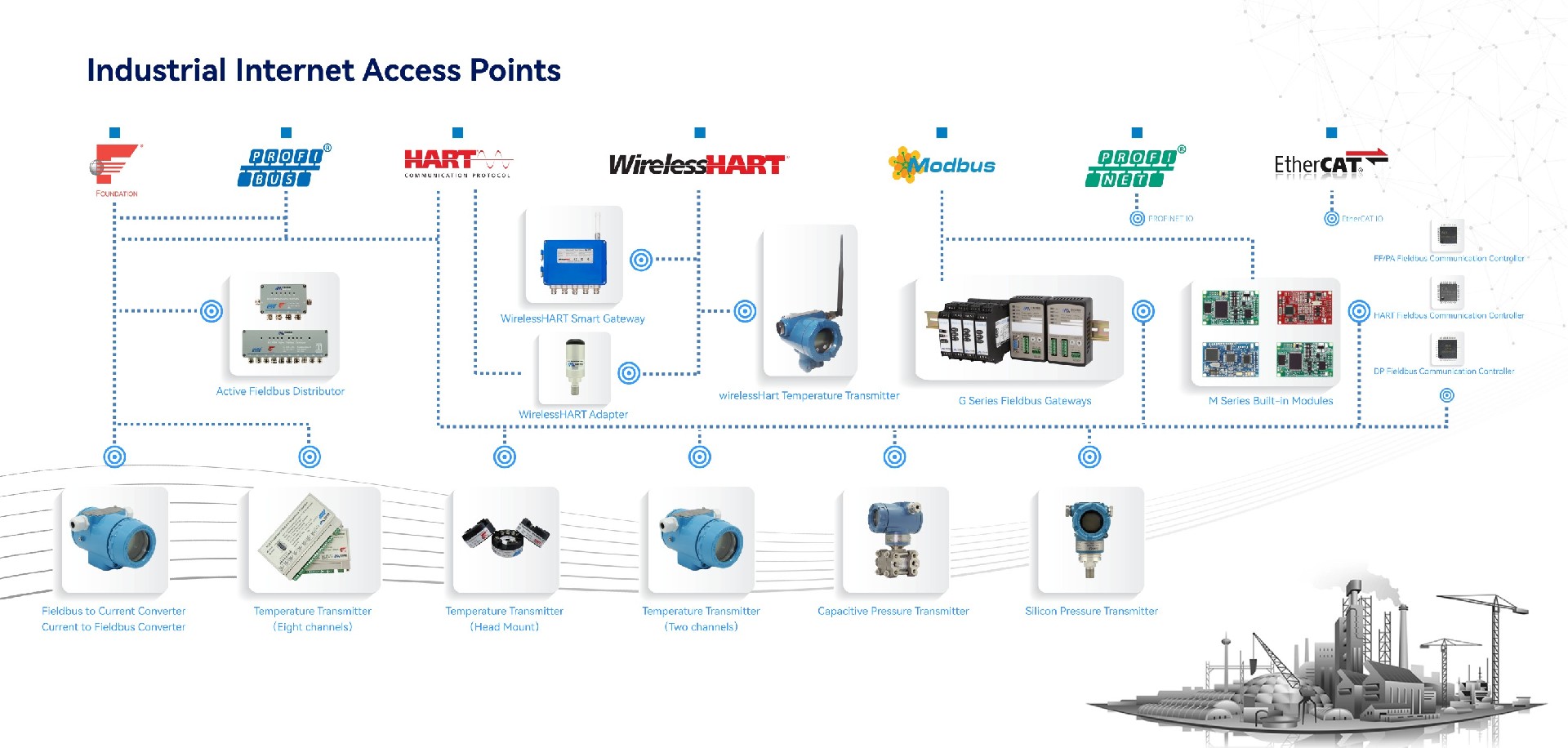

Industrial Internet Access Point

Microcyber is committed to the research and development, production, sales and integrated application of industrial IoT products.

Microcyber is the first fieldbus protocol stack in China and the third in the world to pass international certification, the first fieldbus instrument in China to pass international certification, the first demonstration application of networked control system in China, and the first function in China to pass international certification, the first wireless HART product in China to pass international certification, etc.

Microcyber is one of the main undertaking units of important national science and technology projects in the fields of industrial Internet of Things and industrial automation. Over the years, we had undertaken a number of major national science and technology projects, the National High Technology Research and Development Plan (863 Plan), and the development of intelligent manufacturing equipment. Special projects and other national science and technology plans.

Microcyber has accumulated rich experience in technical capabilities, technical achievements and technical reserves, and has a strong R&D team to protect the sustainable development of the company's products.

<< Previous page

Next page >>