Profound and Detailed

2023-07-21

What is PROFINET ?

PROFINET, launched by PROFIBUS International (PI), is a new generation of automation bus standard based on industrial Ethernet technology. It is mainly used in the field of industrial automation and process control, conforms to the content under the IEEE 802.3 specification, and has the functions of automatic negotiation and automatic crossover.

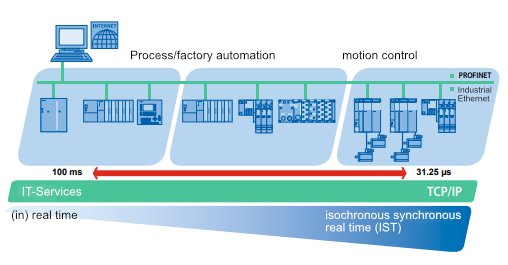

PROFINET belongs to real-time Ethernet, and its communication response time is less than 10ms; PROFINET also supports isochronous communication (IRT), which is used in occasions with strict time requirements such as motion control, and its response time is less than 1ms;

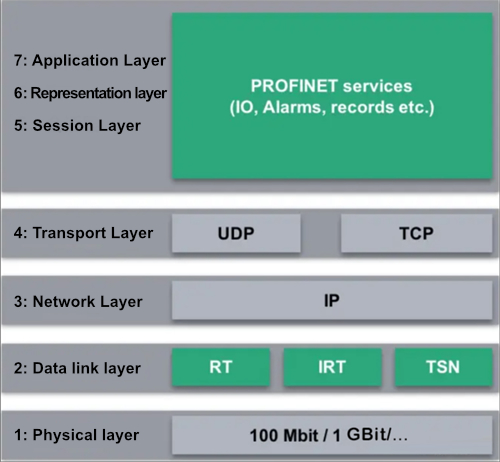

ISO/OSI Reference Model for PROFINET :

The above figure is the OSI reference model of PROFINET. PROFINET uses the physical layer, link layer, network layer, transport layer and application layer protocols. The physical layer specifies the transmission rate of 100M or 1000M. The network layer and transport layer follow the standard of the TCP/IP protocol family, and the uniqueness lies in the specification of the data link layer and application layer.

PROFINET link layer: Refers to standards such as IEEE 802.3, IEEE 802.1Q, and IEC 61784-2, respectively guaranteeing full-duplex, priority labeling, and the ability to implement extensions, so that communication forms such as RT (real-time communication), IRT (isochronous real-time communication), and TSN (time-sensitive network) can be realized.

PROFINET application layer: There are various application layer protocol standards, such as IEC 61784 and IEC 61158 to ensure PROFINET IO services, IEC 61158 Type 10 to ensure PROFINET CBA services, etc.

Features of PROFINET :

1. PROFINET is an open architecture that can be interconnected with the traditional Internet, commonly known as "one network to the end". The so-called "one network to the end" refers to connecting the field layer, control layer and management layer through a network to realize data exchange and facilitate management and maintenance;

2. Support a variety of topological structures, flexible addition and deletion of nodes; PROFINET supports network topologies such as line, star, tree, and ring, and can flexibly add or delete nodes as needed;

3. Support PROFIsafe, PROFIdrive, and PROFIenergy three major profiles, which can realize the functions of safety, motion control and energy saving;

4. High communication rate and extremely low jitter to ensure timely and accurate data exchange;

5. Support the diagnosis function, which can quickly locate the fault node;

PROFINET Application Situation :

PROFINET can realize data transmission services under different delays, ranging from 100ms to 31.25us; according to the application time requirements, several application fields of PROFINET can be divided, such as: motion control field with low latency corresponding to high real-time requirements; process/factory automation field corresponding to medium and high latency.

At present, the global share of PROFINET bus accounts for 25% (DP+PN), which is also the first, which shows that PROFINET bus has a broad market. With the changes in the global industrial control industry in recent years, Siemens has further opened up the access of third parties, so as a third-party manufacturer, it has vested commercial interests, and the addition of third-party products has further enriched PN's ecological network, giving customers more options and complementing each other.

At present, the third-party manufacturers mainly include Rexroth, Phoenix, domestic Inovance, Maixin, Hechuan, etc., and there are also some manufacturers of protocol stack solutions.

<< Previous page

Next page >>